Pressure gauges are a group of devices that measure and display fluid pressure levels (of liquid or gas) inside enclosed vessels or systems. Pressure is nothing more than the measurement of the amount of force applied over a specific unit area. Read More…

At AMETEK® U.S. Gauge, PMT Products, we take pride in designing and manufacturing precision pressure gauges that set the standard for performance and reliability. We specialize in creating instruments that deliver accurate readings under the most demanding industrial conditions, ensuring dependable operation across a wide range of applications.

We take pride in offering a wide range of pressure gauges designed to deliver precision, reliability, and durability across industrial applications. At Emerson, we engineer our gauges to meet the demands of challenging environments where accurate pressure monitoring is critical to performance and safety.

Since 1946, WIKA has continuously advanced instrumentation for pressure, temperature, level, flow, and force measurement. A global leader in lean manufacturing, WIKA has manufacturing locations around the globe, which enables flexibility and the ability to meet high delivery demands.

Ashcroft’s extensive product line is the benchmark in pressure and temperature measurement, including pressure gauges. Used globally in the most demanding environments, our instruments are known under the names Ashcroft®, Heise®, Willy® and Weksler® and offer multi-industry versatility. As a leader in technology and innovation, we design new products for current and emerging market...

Endress + Hauser makes highly accurate equipment with electric output signals, which function as digital process pressure and differential pressure gauges. Our differential pressure gauges measure dusts, gases, liquids and vapors. Ceraphant is our pressure switch used in absolute and pressure gauges.

More Pressure Gauge Manufacturers

Pressure measurement devices play a critical role in a wide range of industrial and commercial applications. Many modern devices convert pressure readings into electric signals for integration with data acquisition devices (DAQ), allowing for advanced monitoring and automation. However, the classic pressure gauge remains a fundamental, direct-reading instrument that displays immediate pressure readings without the need for electronic conversion. Appreciated for their simplicity, reliability, cost-effectiveness, and minimal maintenance needs, pressure gauges are indispensable tools across manufacturing, process industries, HVAC, laboratory environments, and more.

History of Pressure Gauges

The evolution of pressure measurement technology dates back to the early modern era, with roots in the scientific breakthroughs of Evangelista Torricelli, an Italian mathematician and physicist. In 1644, Torricelli’s experiments demonstrated the existence of vacuums and established that air possesses weight—a discovery that set the stage for further advancements by scientists such as Blaise Pascal. The practical development of pressure gauges accelerated during the Industrial Revolution, driven by a growing need for safety and control in steam-powered machinery and locomotive engines.

A pivotal moment in pressure gauge history occurred in the 1840s, when French engineer Eugene Bourdon invented the Bourdon tube pressure gauge. This innovation addressed the pressing safety concerns of high-pressure locomotive engines, dramatically reducing the risk of catastrophic failures. The Bourdon gauge enabled accurate measurement of much higher pressures than was previously possible, revolutionizing industrial safety and efficiency. Today, the Bourdon tube remains the most widely used pressure gauge type, with its robust, reliable design continuously refined for modern applications.

Why Pressure Gauges Matter

Accurate pressure measurement is fundamental to the safe and efficient operation of countless systems. Industrial processes—spanning water treatment plants, oil refineries, chemical manufacturing, gas distribution networks, food processing, and pharmaceuticals—require precise pressure monitoring to ensure equipment safety, product quality, and regulatory compliance. Even everyday products such as water heaters, fire extinguishers, and medical gas cylinders rely on pressure gauges for optimal performance.

- System Reliability: Pressure gauges provide real-time feedback, enabling operators to detect pressure fluctuations, identify leaks, and prevent overpressure events that could cause equipment failure or hazardous conditions.

- Process Optimization: In fluid power systems (hydraulics and pneumatics), pressure readings are essential for maintaining the desired flow rates and ensuring that valves, pumps, and actuators function within safe limits.

- Safety Compliance: Regulatory standards often mandate the use of calibrated pressure gauges in critical applications, making accurate pressure measurement a legal requirement in many industries.

- Energy Efficiency: Monitoring and adjusting system pressure helps minimize energy consumption and reduce operational costs in manufacturing, HVAC, and utility systems.

Given these factors, pressure is among the most frequently measured parameters in industrial settings—second only to temperature. If you’re wondering, “How do I select the right pressure gauge for my application?” or “What are the best practices for pressure monitoring in my industry?”—read on for in-depth guidance.

Materials Used in Pressure Gauge Construction

Choosing the right materials for a pressure gauge is vital for ensuring durability, chemical compatibility, and reliable operation over time. The materials selected depend on the application’s environment, the media being measured, and the pressure range required.

- Chemical and Harsh Environments: Gauges exposed to aggressive chemicals, high humidity, or extreme temperatures—such as those in chemical processing, petrochemicals, power generation, and pharmaceutical manufacturing—require corrosion-resistant construction. Stainless steel is the material of choice for these demanding conditions, offering superior resistance to rust and corrosion.

- Standard Applications: For less corrosive environments or applications involving non-aggressive fluids and gases, pressure gauges are often manufactured with brass or bronze components, which provide adequate performance at a lower cost.

- High-Pressure Conditions: When measuring high system pressures, robust materials such as hardened steel or specialized alloys are used to withstand mechanical stress and prolong the lifespan of the gauge.

- Internal Mechanisms: The internal moving parts—such as the Bourdon tube or diaphragm—are typically constructed from beryllium copper, phosphor bronze, or specialty steel alloys. These materials undergo spring tempering for enhanced elasticity, ensuring precise movement and longevity.

Pressure gauges are available in a variety of sizes and mounting configurations, enabling integration into compact spaces or large industrial tanks. Custom pressure gauges can be engineered for unique requirements, including high-vibration environments, sanitary processes, and hazardous locations. Looking for a pressure gauge that fits your specific installation constraints? Explore our directory of pressure gauge manufacturers for tailored solutions.

How Pressure Gauges Work

Pressure gauges operate by translating mechanical pressure into a visual or digital display. The pressure itself provides the energy required for measurement—no external power is needed for analog gauges. At the end of manufacturing, every pressure gauge undergoes calibration against a master gauge to ensure accuracy. After calibration, the device is ready for installation at key points in hydraulic, pneumatic, or process systems, such as at pump outlets, regulator stations, or process vessels.

Pressure gauges fall into two main categories: analog and digital. Each type offers distinct advantages and is suited to different use cases:

Analog Pressure Gauges

Traditional analog gauges use a needle and dial to indicate pressure. The core component is an elastic chamber (typically a Bourdon tube, bellows, or diaphragm) that deforms in response to applied pressure. This mechanical movement is transferred through a gear mechanism, causing the needle to move along a graduated scale.

- Bourdon Tube Gauges: The most prevalent analog gauge type, the Bourdon tube is a curved, C-shaped metal tube that straightens as internal pressure increases. This movement drives the needle, providing a clear visual indication of pressure. Spiral and helical versions are also available for measuring higher pressures.

- Bellows Gauges: These gauges use accordion-like metal chambers that expand and contract with pressure changes. Bellows are ideal for low-pressure and differential pressure measurement in sensitive applications.

- Diaphragm Gauges: A thin, flexible metal membrane deforms with pressure changes. Diaphragm gauges are often used where corrosion resistance or sanitary design is required, such as in food and beverage or pharmaceutical processes.

Digital Pressure Gauges

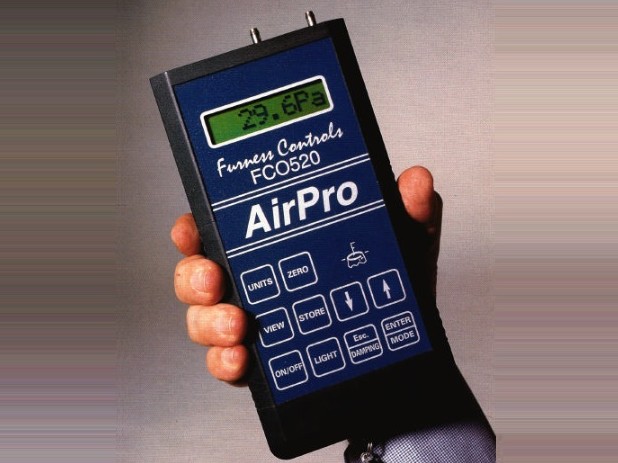

Digital pressure gauges are gaining popularity due to their high accuracy, easy-to-read displays, and ability to interface with digital control systems. These gauges require an external power source, such as batteries or a direct electrical connection. They utilize advanced pressure sensors—often based on strain gauge or piezoelectric technology—to convert mechanical pressure into an electronic signal, which is then processed and displayed as a precise digital value.

- Strain Gauge Sensors: Detect changes in electrical resistivity as pressure deforms a sensing element, providing accurate and repeatable readings.

- Piezoelectric Sensors: Measure electrical charges generated in response to mechanical pressure, offering excellent dynamic response and stability.

Digital gauges are ideal for process control, laboratory calibration, and any application requiring data logging, remote monitoring, or integration with supervisory systems.

Curious about the differences between analog and digital pressure gauges? Learn more about digital pressure gauge technology and suppliers here.

Types of Pressure Gauges and Their Applications

To meet the diverse requirements of industrial, commercial, and laboratory processes, manufacturers offer a variety of pressure gauge types, each tailored to specific substances, pressure ranges, or application environments. Selecting the right gauge depends on the medium being measured, the desired measurement accuracy, and the operational conditions.

Gauges Classified by the Substance They Measure

- Water Pressure Gauges: Designed to monitor pressure in water supply systems, filtration units, boilers, irrigation systems, and more. These gauges help maintain optimal performance in plumbing, municipal waterworks, and industrial process water circuits.

- Air Pressure Gauges: Used to monitor pneumatic pressure in air compressors, HVAC systems, pneumatic tools, and manufacturing equipment. Essential for maintaining safe operation and energy efficiency.

- Oil Pressure Gauges: Measure oil pressure in lubrication systems, hydraulic machinery, automotive engines, and heavy equipment. Monitoring oil pressure helps prevent equipment damage due to inadequate lubrication or leaks.

- Gas Pressure Gauges: Track pressure in natural gas pipelines, industrial gas systems, and medical gas supply lines. Accurate gas pressure measurement is critical for safety and regulatory compliance.

- Fuel Pressure Gauges: Common in automotive, aerospace, and marine applications, these gauges indicate the pressure of gasoline, diesel, or alternative fuels in delivery systems.

Gauges Classified by Pressure Range and Function

- High Pressure Gauges: Built for environments where hydraulic or pneumatic pressures exceed standard ratings, such as hydrodemolition, hydroblasting, waterjet cutting, and industrial hydraulic systems. Durable construction ensures safety and longevity under extreme conditions.

- Low Pressure Gauges: Highly sensitive instruments capable of detecting small pressure variations, typically between ten and fifteen PSI. Used in laboratory settings, cleanrooms, and applications where precise measurement of low pressures is essential (e.g., air flow monitoring, filter testing, or leak detection).

- Vacuum Pressure Gauges: Measure pressures below atmospheric levels, useful for vacuum pumps, packaging equipment, freeze-drying systems, and scientific research. Maintaining proper vacuum levels is vital for product quality and system performance.

- Seal Gauges: Incorporate diaphragm seals to isolate the gauge mechanism from corrosive, viscous, or contaminated process media. Widely used in chemical, petrochemical, food and beverage, and pharmaceutical industries to prevent leaks and ensure sanitary operation.

- Differential Pressure Gauges: Measure the difference in pressure between two points in a process system. Key applications include monitoring filter condition, pump efficiency, and flow rates in HVAC, water treatment, and industrial filtration systems.

Gauges Classified by Standards of Pressure Reference

- Gauge Pressure Gauges: Indicate pressure relative to atmospheric pressure, commonly used in everyday industrial and mechanical systems.

- Absolute Pressure Gauges: Measure pressure relative to a perfect vacuum, essential for scientific research, high-precision manufacturing, and processes sensitive to atmospheric fluctuations.

- Sealed Pressure Gauges: Use a fixed reference pressure (rather than atmospheric) for measurement. Useful in applications where external atmospheric conditions fluctuate or are not relevant.

Have questions like “What type of pressure gauge is best for my chemical processing system?” or “Do I need a differential or absolute pressure gauge for my application?”? Contact our experts or browse top pressure gauge manufacturers here.

Application-Specific Pressure Gauges

- Magnehelic Gauges: Specialized differential pressure gauges commonly used in HVAC systems to measure static pressure, airflow, and filter performance.

- Dial and Weighted Gauges: Used in pressure canners, autoclaves, and laboratory sterilizers to provide reliable, easy-to-read pressure measurement.

- Test Gauges: Precision instruments designed for calibration and quality assurance, offering high accuracy and traceability for laboratory or field testing.

Still not sure which type of pressure gauge is right for your system? Explore our detailed manufacturer listings or use our Pressure Gauge Selection Guide for tailored recommendations.

Pressure Gauge Accessories and Enhancements

To maximize functionality, accuracy, and protection, pressure gauges are often paired with a variety of accessories and complementary devices. These additions extend the life of the gauge, enhance measurement precision, and add safety or automation features:

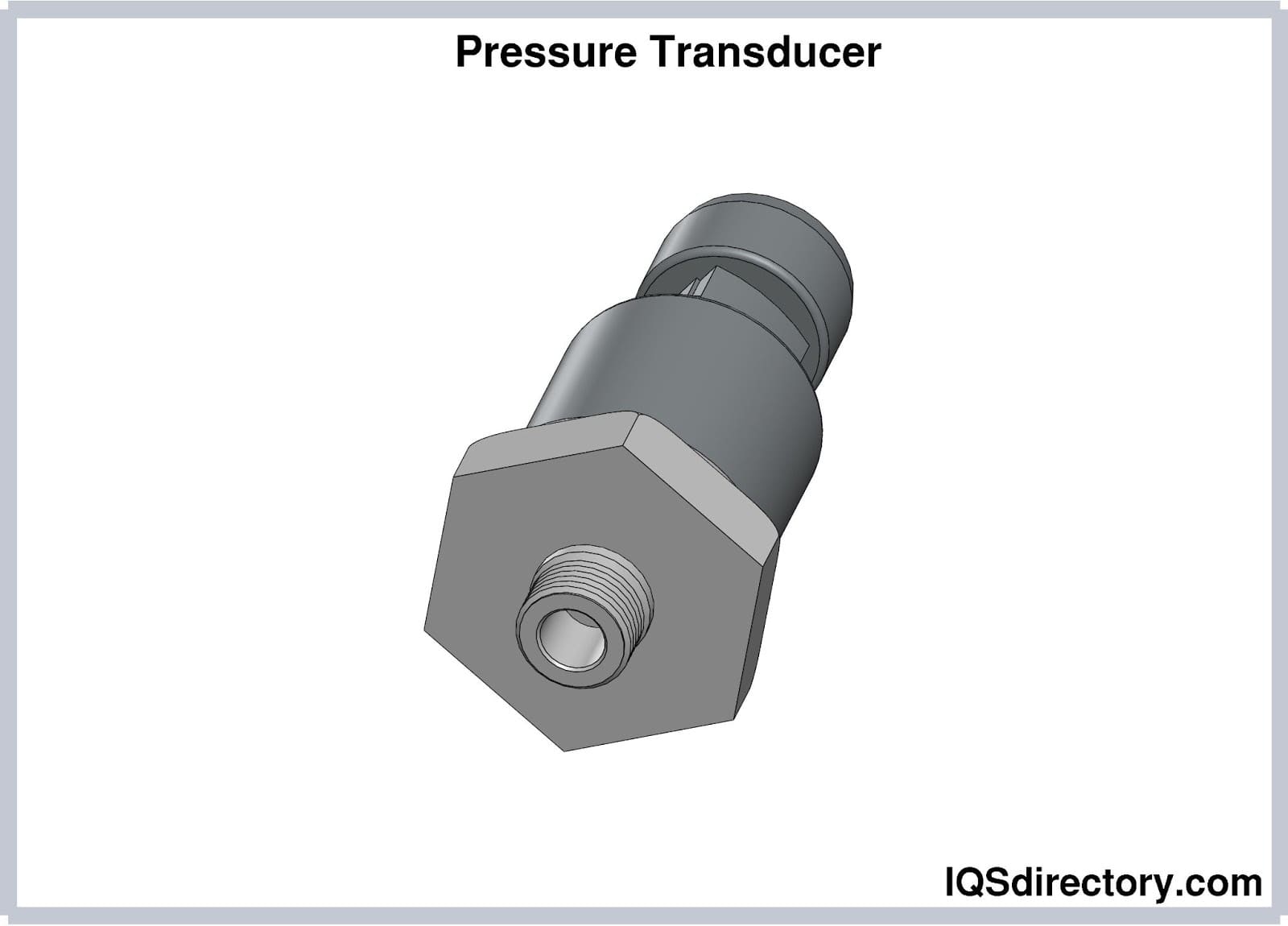

- Pressure Sensors and Transducers: Convert mechanical pressure into electrical signals, enabling integration with digital control systems, PLCs, or remote monitoring platforms. Ideal for industrial automation and IIoT (Industrial Internet of Things) applications.

- Pressure Transmitters: Amplify and transmit pressure readings over long distances, allowing centralized data collection and process control.

- Switches and Alarms: Set pressure thresholds to trigger alarms, signal lights, or automatic shutdowns, enhancing operational safety and process reliability.

- Test Point Adapters: Allow quick, convenient connection of gauges at various system locations for spot checks or troubleshooting without the need for multiple dedicated gauges.

- Gauge Isolators: Protect the gauge from pressure surges or process contamination. These devices isolate the gauge from the system until a reading is required, extending service life and improving safety.

- Snubbers and Dampeners: Minimize the effects of pulsation or vibration on the gauge needle, stabilizing readings and reducing wear.

- Chemical Seals: Protect the gauge mechanism from corrosive or clogging process media, ensuring long-term reliability in harsh environments.

- Case Protectors and Covers: Shield the gauge from impact, moisture, or dust, supporting consistent performance in rugged or outdoor settings.

Investing in the right accessories can significantly improve the accuracy, durability, and safety of your pressure measurement system. Need help choosing accessories for your pressure gauges? Browse our supplier directory or contact us for expert advice.

Key Considerations When Selecting a Pressure Gauge

Choosing the appropriate pressure gauge for your application involves careful evaluation of several key factors. The right selection ensures accurate measurements, system safety, and long-term reliability. Consider the following:

- Pressure Range: Select a gauge with a full-scale range approximately twice the normal operating pressure. This provides a safety margin and helps prevent overloading or damage to the gauge. As a rule, never operate a gauge above three-quarters of its maximum reading.

- Dial Size: Larger dials are easier to read from a distance but may not fit in compact installations. Choose a size that balances visibility with available space.

- Connection Type and Size: Ensure the gauge’s threaded or flanged connection matches your system’s requirements (e.g., NPT, BSP, flange-mount, or sanitary tri-clamp).

- Units of Measurement: Confirm that the gauge displays units compatible with your process (e.g., PSI, bar, kPa, mmHg, Pa).

- Material Compatibility: Select materials for wetted parts that resist corrosion, abrasion, and chemical attack from the process media.

- Operating Environment: Consider temperature extremes, vibration, humidity, and exposure to corrosive or explosive atmospheres. Protective accessories may be needed for harsh conditions.

- Dry vs. Liquid-Filled: Liquid-filled gauges (often filled with glycerin or silicone) dampen needle vibration and extend gauge life in high-pulsation or high-vibration environments. Dry gauges are preferred for stable, clean environments.

- Accuracy Class: Depending on the application, accuracy requirements may range from ±0.1% for test gauges to ±2% for general-purpose industrial gauges. Choose a class appropriate for process criticality.

Application-Specific Considerations

- Hydraulic Systems: Use hydraulic pressure gauges designed for the expected pressure range and compatible with hydraulic fluids. These gauges typically feature robust construction and shock-resistant cases.

- Sanitary Applications: Select gauges with diaphragm seals and easy-to-clean surfaces for food, beverage, or pharmaceutical processes.

- Low-Pressure Measurement: For low-pressure or differential applications, opt for bellows or diaphragm-type gauges that offer high sensitivity and incremental accuracy.

- Digital Requirements: For processes requiring digital integration, data logging, or remote monitoring, choose a digital pressure gauge or a gauge with an integrated pressure transmitter.

Wondering, “What is the best pressure gauge for my hydraulic system?” or “How do I ensure my gauge is compatible with corrosive process fluids?” Our pressure gauge manufacturers offer a wide range of options and can provide expert guidance tailored to your needs.

Pressure Gauge Calibration, Maintenance, and Best Practices

Regular calibration and proper maintenance are essential for ensuring pressure gauge accuracy and reliability. Over time, mechanical wear, fatigue, or exposure to harsh conditions can impact gauge performance. Implement these best practices to safeguard your pressure measurement system:

- Calibration: Periodically verify gauge readings against certified standards or master gauges. Many suppliers offer on-site or laboratory calibration services to maintain compliance with industry regulations (e.g., ISO, ASME, NIST).

- Inspection: Routinely inspect gauges for signs of damage, leaks, needle vibration, or case fogging. Replace gauges that show wear or have exceeded their recommended service life.

- Maintenance: Clean gauges and accessories regularly, especially in dusty, wet, or corrosive environments. For liquid-filled gauges, check for fluid level and replace fill fluid as needed.

- Record-Keeping: Maintain accurate records of calibration dates, maintenance activities, and gauge replacements to support quality assurance and regulatory compliance.

Looking for reliable calibration and maintenance services? Find trusted pressure gauge service providers here.

Benefits of Working with Leading Pressure Gauge Manufacturers

Partnering with experienced and reputable pressure gauge manufacturers delivers several advantages:

- Comprehensive Product Range: Access to a broad selection of pressure gauges, sensors, transmitters, and accessories to meet virtually any application requirement.

- Customization: Ability to source custom-engineered gauges for unique environments, specialty media, or challenging installation conditions.

- Technical Support: Expert assistance with product selection, configuration, installation, and troubleshooting.

- Quality Assurance: Confidence in product reliability, compliance with industry standards, and traceable calibration certificates.

- Aftermarket Services: Ongoing calibration, maintenance, and repair support to ensure long-term performance and safety.

Seeking a pressure gauge supplier with a proven track record? Browse our curated list of pressure gauge manufacturers and service providers to find the right partner for your project.

Common Questions and Buying Guide

When researching or purchasing pressure gauges, you might ask:

- What type of gauge is best for my specific industry (e.g., chemical, oil & gas, food processing, automotive)?

- How do I interpret pressure gauge accuracy classes?

- Should I invest in analog or digital gauges for my facility?

- What mounting options are available for confined spaces?

- How do I calibrate and maintain my pressure gauges to ensure ongoing accuracy?

- What are the signs that a pressure gauge needs replacement?

For answers to these questions and more, consult our Pressure Gauge Buying Guide or connect with industry-leading suppliers for personalized advice.

Conclusion

Pressure gauges remain a vital component of industrial, commercial, and laboratory systems, offering unmatched simplicity, reliability, and versatility in pressure measurement. Whether you need robust analog gauges for heavy-duty manufacturing, sanitary gauges for food processing, or advanced digital models for process automation, the right pressure gauge ensures operational safety, process efficiency, and regulatory compliance.

Ready to enhance your pressure measurement capabilities? Explore our directory of top pressure gauge manufacturers or reach out to our experts for help selecting the best solution for your needs. Invest in quality, reliability, and expert support—choose the right pressure gauge for your application today.

What are the main types of pressure gauges and their uses?

Pressure gauges come in various types such as analog (Bourdon tube, bellows, and diaphragm) and digital gauges. Analog gauges are commonly used in industrial settings for direct, real-time readings, while digital gauges offer high accuracy, easy data logging, and integration with control systems. Specialized gauges measure different substances (water, air, oil, gas, and fuel) and operate across ranges including high, low, differential, or vacuum pressures, with applications spanning HVAC, laboratories, hydraulic systems, and chemical processing.

How do I select the right pressure gauge for my application?

Selecting the appropriate pressure gauge involves evaluating factors such as operating pressure range, dial size for visibility, connection type and size, units of measurement, material compatibility with process media, the application environment, accuracy class, and whether you need a dry or liquid-filled gauge. For special requirements like sanitary or digital needs, ensure to select gauges tailored for those applications.

What materials are used in pressure gauge construction and why are they important?

Pressure gauges are constructed from materials such as stainless steel, brass, bronze, hardened steel, and specialty alloys. The choice depends on the process environment and media: stainless steel provides corrosion resistance for harsh environments, brass and bronze are for standard, non-corrosive applications, and specialized alloys or treated metals are used in high-pressure or chemically aggressive scenarios. Proper material selection ensures durability, safety, and gauge longevity.

What is the difference between analog and digital pressure gauges?

Analog pressure gauges display readings with a mechanical needle and dial using elements like Bourdon tubes or diaphragms. They do not require external power and are valued for simplicity and reliability. Digital gauges use electronic sensors (strain gauge or piezoelectric) to provide precise digital readouts and often support data logging and integration with control systems, but they require an external power source.

How should pressure gauges be maintained and calibrated?

Regular calibration against certified standards is essential to ensure accuracy. Maintenance should include periodic inspections for damage, leaks, or vibration, cleaning, checking liquid-filled gauges for fluid level, and record-keeping of all calibration and service activities. Gauges should be replaced if they exceed their service life or show signs of wear compromising safety or accuracy.

Why are pressure gauges important in industrial and commercial applications?

Pressure gauges are crucial for ensuring system reliability, process optimization, safety compliance, and energy efficiency. They provide real-time monitoring to detect leaks, prevent overpressure, ensure equipment operates within safe limits, and meet regulatory standards. Accurate pressure monitoring protects both equipment and personnel while enhancing product quality and minimizing operational costs.

What accessories can enhance pressure gauge performance and lifespan?

Accessories such as pressure sensors, transmitters, alarm switches, test point adapters, gauge isolators, snubbers, chemical seals, and protective covers can improve measurement precision, protect the gauge from harsh conditions or pulsation, enable integration with automation systems, and extend gauge life, safety, and functional versatility in demanding environments.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services