Pressure gauges provide a variety of benefits in many different industries. Without pressure gauges, it would be impossible to determine the pressure in an object or container. Pressure readings are necessary to ensure the safety of containers, employees, and the materials inside the pressurized containers. Pressure gauges are used with everything from tire pressure to the pressure of containers of steam used for boilers and much more. Each kind of pressure gauge has its own method of measurement.

Air pressure gauges: Air pressure gauges work by measuring the ideal amount of gas that a container requires to maintain ideal pressure. Usually, this is used for tires and other inflatable products to prevent them from going flat or exploding.

Oil/hydraulic pressure gauges: Hydraulic pressure gauges use hydraulic fluid or oil to lubricate the parts of a machine to prevent excessive friction that can damage the machine. The gauge identifies whether there is enough fluid to lubricate the object properly.

Differential pressure gauges: A differential pressure gauge can show the variation in pressure between two containers by the fluid inside of a “U” shaped tube. This system has two entrance ports with either port connected to a separate container for easy pressure comparison.

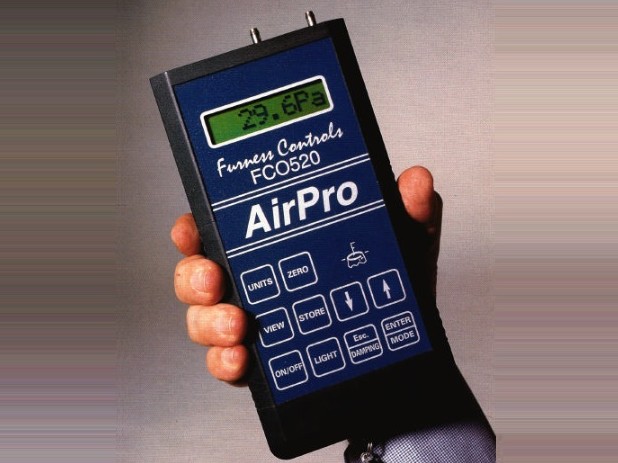

Digital pressure gauges: Digital pressure gauges convert pressure readings into a digital display. This makes it easier to make pressure readings where accuracy is extremely important.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services