A digital pressure gauge is a device that displays the amount of measured pressure in an integrated digital display. It senses the pressure from gas and displays it in digital format. It does not require an operator to read the pressure value from the needle’s position as analog pressure gauges do. Instead, a digital pressure gauge utilizes a transducer. The transducer functions to convert the pressure value into an electrical signal. The electrical signal is the one that reflects the amount of the pressure reading. Read More…

At AMETEK® U.S. Gauge, PMT Products, we take pride in designing and manufacturing precision pressure gauges that set the standard for performance and reliability. We specialize in creating instruments that deliver accurate readings under the most demanding industrial conditions, ensuring dependable operation across a wide range of applications.

We take pride in offering a wide range of pressure gauges designed to deliver precision, reliability, and durability across industrial applications. At Emerson, we engineer our gauges to meet the demands of challenging environments where accurate pressure monitoring is critical to performance and safety.

Since 1946, WIKA has continuously advanced instrumentation for pressure, temperature, level, flow, and force measurement. A global leader in lean manufacturing, WIKA has manufacturing locations around the globe, which enables flexibility and the ability to meet high delivery demands.

Ashcroft’s extensive product line is the benchmark in pressure and temperature measurement, including pressure gauges. Used globally in the most demanding environments, our instruments are known under the names Ashcroft®, Heise®, Willy® and Weksler® and offer multi-industry versatility. As a leader in technology and innovation, we design new products for current and emerging market...

Endress + Hauser makes highly accurate equipment with electric output signals, which function as digital process pressure and differential pressure gauges. Our differential pressure gauges measure dusts, gases, liquids and vapors. Ceraphant is our pressure switch used in absolute and pressure gauges.

More Digital Pressure Gauge Manufacturers

Digital pressure gauges have become essential tools in a wide spectrum of industries, offering higher accuracy, reliability, and data flexibility compared to traditional analog gauges. Depending on the specific application and technical requirements, users can choose from a variety of digital pressure gauge types, each engineered to meet the demands of modern process measurement, control, and monitoring.

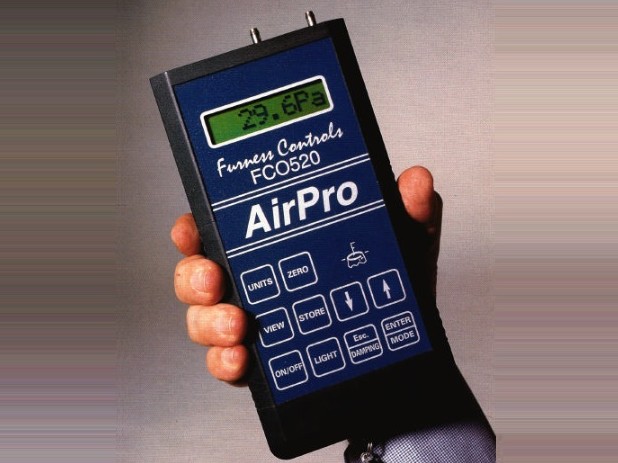

There are both portable digital pressure gauges and permanently installed digital pressure gauge models. Portable digital pressure gauges are ideal for field work, calibration, and troubleshooting, allowing technicians to move the device from point to point for on-site, local pressure readings. Installed digital pressure gauges, by contrast, are designed for integration into fixed systems such as process pipelines, industrial machinery, HVAC installations, or laboratory setups. These gauges are intended for continuous monitoring and are more permanent in their application, often forming a critical part of industrial automation, process control, and safety protocols.

Unlike their analog counterparts, digital pressure gauges require a power source to function—typically batteries, external power supplies, or solar panels. This power requirement enables them to offer advanced features such as digital displays, backlighting, data logging, connectivity for remote monitoring, and programmable alarm functions. As a result, digital pressure gauges have become the instrument of choice in applications where accuracy, repeatability, and data accessibility are key considerations.

The Working Principle of a Digital Pressure Gauge

At the core of every digital pressure gauge is a pressure sensor that converts the physical force exerted by a fluid (gas or liquid) into an electronic signal. This transformation is fundamental for providing precise, real-time digital readouts. The most widely used sensor technology in digital pressure gauges is the piezoresistive pressure sensor. This type of sensor incorporates a thin diaphragm embedded with piezoresistive elements. When pressure is applied, the diaphragm deflects, altering the electrical resistance of these elements. This change in resistance is directly proportional to the applied pressure and is converted into a digital signal, which the gauge's microprocessor then interprets and displays as a pressure value in the selected measurement unit.

Other sensor technologies found in digital pressure gauges include capacitive, strain gauge, and resonant silicon sensors. Each has specific advantages for certain measurement ranges, media compatibility, and environmental conditions. For example, capacitive sensors are well-suited for low-pressure measurements, while strain gauge sensors are ideal for high-pressure industrial applications.

Types of Digital Pressure Gauges

Digital pressure gauges are classified according to their reference pressure and intended measurement function. Selecting the right type of digital pressure gauge is critical for achieving accurate pressure readings and ensuring compatibility with your process requirements. The primary types are:

Gauge Pressure

A gauge pressure digital pressure gauge is vented to the atmosphere and measures pressure relative to the current atmospheric pressure, which fluctuates with changes in weather and altitude. This type of gauge is commonly used when only positive pressures need to be monitored, such as in water supply systems, tire inflation, or hydraulic circuits. The measurement output reflects the pressure above atmospheric conditions, making it ideal for everyday industrial and automotive use.

Compound Pressure Gauge

Compound pressure digital gauges are designed to measure both positive and negative (vacuum) pressures. These gauges feature dials or digital readouts that can indicate pressure values above and below atmospheric pressure. Compound digital pressure gauges are critical in applications where both vacuum and positive pressure need to be monitored, such as in HVAC systems, laboratory test chambers, and leak detection in pressurized lines. The ability to read dual ranges makes these gauges versatile solutions in complex process environments.

For example, in a laboratory test chamber, a compound digital pressure gauge enables researchers to monitor vacuum levels during evacuation and positive pressure during pressurization cycles, all on a single device. This dual functionality supports greater process control and ensures safety during system transitions.

Vacuum Pressure Gauge

Vacuum pressure gauges are specialized digital pressure measuring devices calibrated specifically to read negative pressure—i.e., pressures that are lower than ambient atmospheric pressure. These gauges are essential in applications such as vacuum packaging, freeze drying, distillation, semiconductor manufacturing, and cleanroom environments. The digital readout provides precise vacuum measurements, ensuring critical processes remain within required tolerances and quality standards. Typically, these gauges display zero at atmospheric pressure, with descending values as pressure decreases below atmospheric levels.

Sealed Pressure Gauge

A sealed digital pressure gauge uses a reference chamber that is permanently sealed at the factory, rather than vented to the atmosphere. This design is particularly advantageous in harsh, dusty, wet, or dirty environments where the risk of contamination or moisture ingress could compromise gauge performance. Sealed pressure gauges are commonly used in process industries, marine environments, and outdoor applications where environmental protection and long-term reliability are paramount. They are typically used for measuring positive pressure relative to the sealed reference.

Absolute Pressure Gauge

An absolute digital pressure gauge measures pressure relative to a perfect vacuum (zero reference pressure). The reference chamber is sealed under a full vacuum during manufacturing. This type of digital pressure gauge is critical in applications demanding absolute accuracy, such as atmospheric studies, meteorology, altitude simulation, and certain chemical and pharmaceutical processes. Unlike gauge or compound types, absolute pressure gauges indicate total pressure, independent of atmospheric fluctuations.

Key Applications of Digital Pressure Gauges

Digital pressure gauges are utilized in a vast array of industries and technical processes, thanks to their precision, versatility, and capacity for integration with modern data systems. Common application areas include:

- Industrial Process Control: Monitoring and regulating process pressures in pipelines, reactors, and storage vessels within oil & gas, petrochemical, and chemical plants.

- Laboratory and Research: Providing highly accurate pressure readings for scientific experiments, calibration labs, and quality assurance testing.

- HVAC and Building Automation: Ensuring optimal performance of heating, ventilation, and air conditioning systems by monitoring duct and refrigerant pressures.

- Pharmaceutical and Food Processing: Maintaining precise pressure conditions in clean rooms, sterile environments, and production lines that require rigorous quality control.

- Automotive and Aerospace: Measuring fuel, oil, hydraulic, tire, and manifold pressures during manufacturing, testing, and maintenance.

- Water and Wastewater Management: Monitoring pressures in water treatment plants, distribution systems, and sewage networks for operational safety and compliance.

- Power Generation: Tracking steam and gas pressures within boilers, turbines, and ancillary systems to optimize efficiency and safety.

- Medical and Healthcare: Used in devices such as ventilators, anesthesia machines, and blood pressure monitors where real-time, accurate readings are critical.

- Calibration and Service: Portable digital pressure gauges serve as reference standards for calibrating other pressure measuring instruments in the field or laboratory.

Benefits of Digital Pressure Gauges

Digital pressure gauges offer a host of advantages over traditional mechanical gauges, making them the preferred choice for modern measurement and control applications. Key benefits include:

- High Accuracy and Precision: Advanced sensor technology enables digital gauges to deliver highly accurate and repeatable readings, often with lower error margins than analog alternatives.

- Multi-Unit Display Capability: Readings can be instantly displayed in various pressure units (e.g., psi, bar, kPa, MPa, inHg), allowing users to select the most convenient measurement system without manual conversion.

- Elimination of Parallax Error: Digital displays provide clear, direct numerical readings, eliminating the risk of misinterpreting needle positions common to analog gauges.

- Backlit and Easy-to-Read Displays: Modern digital pressure gauges feature high-contrast, backlit LCD or LED screens, enabling accurate readings even in low-light or challenging conditions.

- Data Logging and Connectivity: Many digital pressure gauges are equipped with onboard memory, USB, Bluetooth, or wireless interfaces for recording measurements, remote monitoring, and integration with SCADA or data acquisition systems.

- Programmable Alarms and Control: Some models offer customizable high/low pressure alarms, relay outputs, and process control capabilities.

- Wide Pressure Range Selection: Digital pressure gauges are available in a broad range of measurement capacities, from ultra-low vacuum to extremely high pressures, providing flexibility for diverse applications.

- Shock and Vibration Resistance: Unlike analog gauges, which can suffer from bouncing needles in high-vibration environments, digital gauges provide stable, reliable readings.

- Reduced Operator Training: Simple, intuitive interfaces make digital pressure gauges easy to use for both new and experienced personnel.

- Long-Term Reliability and Low Maintenance: Digital devices typically feature fewer moving parts, reducing maintenance requirements and extending service life.

Limitations and Considerations for Digital Pressure Gauges

While digital pressure gauges provide substantial advantages in measurement accuracy and functionality, users should be aware of certain limitations and factors influencing their selection:

- Limited Power Source: Digital pressure gauges require a power supply, usually batteries or an external power source. Battery-powered models are portable but require periodic battery replacement or recharging. Solar-powered variants offer an eco-friendly alternative but necessitate consistent exposure to light.

- Trend Visibility: Mechanical gauges allow users to observe pressure trends or rapid fluctuations via needle movement, which is less intuitive with digital readouts. Some advanced digital models offer graphical trend displays to mitigate this limitation.

- Environmental Sensitivity: While many digital pressure gauges are ruggedized, extreme temperatures, electromagnetic interference, or moisture ingress can potentially affect their performance. It is essential to select a gauge with an appropriate ingress protection (IP) rating and environmental specifications for your application.

- Initial Cost: Digital pressure gauges may have a higher upfront cost compared to basic analog models. However, their enhanced features, accuracy, and operational efficiencies often justify the investment over time.

- Complexity: Advanced features such as data logging, programmable alarms, and communications protocols can add complexity to setup and operation. Ensure that personnel are adequately trained and the user interface meets your operational requirements.

How to Select the Best Digital Pressure Gauge for Your Application

Choosing the right digital pressure gauge involves evaluating several key criteria to ensure optimal performance and long-term reliability. Here are critical factors to consider when researching and selecting digital pressure gauges for industrial, laboratory, or commercial use:

- Pressure Range and Type: Define the minimum and maximum pressures your application will encounter, and determine whether you require gauge, compound, vacuum, absolute, or sealed measurement capabilities.

- Accuracy Requirements: Consider the required measurement accuracy and resolution. Some applications, such as calibration labs, demand ultra-high accuracy (e.g., ±0.05% FS), while others can tolerate wider margins.

- Media Compatibility: Ensure the sensor and wetted materials are compatible with the process fluid (e.g., air, water, oil, corrosive chemicals, or gases).

- Environmental Conditions: Evaluate operating temperature, humidity, vibration, and potential exposure to dust, water, or corrosive atmospheres. Look for models with suitable IP ratings and rugged construction.

- Display and Interface Features: Assess the visibility and usability of the digital display, backlighting, button controls, and whether the gauge supports data logging, wireless connectivity, or remote monitoring.

- Output and Integration: If you require integration with control systems, SCADA, or data acquisition platforms, select a gauge with analog outputs (e.g., 4-20mA, 0-10V), digital interfaces (RS232, USB, Modbus), or wireless options (Bluetooth, Wi-Fi).

- Power Source: Decide whether portability (battery-powered), continuous operation (AC-powered), or energy efficiency (solar-powered) is most important for your application.

- Calibration and Maintenance: Consider how easily the gauge can be recalibrated or serviced, and whether the manufacturer provides calibration certificates or local support.

- Certification and Compliance: In regulated industries, ensure the digital pressure gauge meets relevant standards (such as CE, RoHS, ATEX, or ISO certifications).

- Cost of Ownership: Evaluate not just the purchase price, but also maintenance, calibration, and potential downtime costs over the product’s lifetime.

Frequently Asked Questions About Digital Pressure Gauges

How do I know which digital pressure gauge is right for my process?

Start by identifying the pressure range, media, and measurement type (gauge, absolute, compound, or vacuum) required for your application. Consider the operating environment, required accuracy, display features, and whether data logging or remote monitoring is needed. Consult the technical datasheets and reach out to manufacturers for recommendations tailored to your industry and use case.

What are the most common applications for digital pressure gauges?

Digital pressure gauges are widely used in industrial process control, HVAC systems, laboratory testing, food and pharmaceutical production, water treatment, automotive maintenance, and calibration services. Their versatility makes them valuable instruments for ensuring safety, quality, and operational efficiency across many sectors.

Why should I choose a digital pressure gauge over an analog gauge?

Digital pressure gauges provide greater accuracy, easier-to-read displays, multiple unit options, and advanced features like data logging and alarms. They also eliminate parallax error and are less affected by vibration or shock, making them more reliable for critical measurements and modern automated systems.

Do digital pressure gauges require regular calibration?

Yes. For accuracy and compliance with industry standards, digital pressure gauges require periodic calibration. The calibration frequency depends on the application, manufacturer recommendations, and regulatory requirements. Many suppliers offer calibration services and certificates to ensure traceability and audit compliance.

Can digital pressure gauges be used for hazardous or corrosive environments?

Many digital pressure gauges are constructed with stainless steel or other corrosion-resistant materials and are available with ATEX or explosion-proof certifications for use in hazardous areas. Always verify sensor compatibility and certifications before deploying in such environments.

How long do digital pressure gauge batteries last?

Battery life varies depending on display type, backlight usage, data logging frequency, and ambient temperature. Some models can operate for months or even years on a single battery, while others with advanced features or continuous backlighting may require more frequent battery changes or recharging.

Choosing the Correct Digital Pressure Gauge Supplier

To ensure optimal results when purchasing digital pressure gauges from a reputable manufacturer or supplier, it’s important to compare several digital pressure gauge companies. Start by reviewing at least four or five manufacturers, utilizing our comprehensive list of digital pressure gauge suppliers. Each supplier’s business profile details their technical expertise, product range, quality management systems, and unique capabilities. Direct communication with manufacturers—using the provided contact forms—allows you to obtain quotes, clarify technical specifications, and request application-specific advice.

Additionally, our proprietary website previewer lets you efficiently research each digital pressure gauge company’s website, helping you identify which suppliers best meet your project or operational requirements. When you’re ready, use our streamlined RFQ (request for quote) form to contact multiple digital pressure gauge companies simultaneously with your inquiry. This approach ensures you receive competitive pricing, technical support, and confidence in your supplier selection for any industrial, laboratory, or commercial application.

By following these steps and carefully evaluating the technical features, certifications, and support services offered by leading digital pressure gauge suppliers, you can make an informed decision that delivers accuracy, reliability, and value for your specific measurement needs.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services