Fuel pressure gauges are a crucial component in monitoring the fuel pressure levels in a fuel system. They provide accurate readings of the fuel pressure and help detect any issues with the fuel system. In this article, we’ll discuss the various components found in fuel gauges, explain how these components work together in a functioning fuel pressure gauge, and examine the different variations and applications of fuel pressure gauges. Read More…

At AMETEK® U.S. Gauge, PMT Products, we take pride in designing and manufacturing precision pressure gauges that set the standard for performance and reliability. We specialize in creating instruments that deliver accurate readings under the most demanding industrial conditions, ensuring dependable operation across a wide range of applications.

We take pride in offering a wide range of pressure gauges designed to deliver precision, reliability, and durability across industrial applications. At Emerson, we engineer our gauges to meet the demands of challenging environments where accurate pressure monitoring is critical to performance and safety.

Since 1946, WIKA has continuously advanced instrumentation for pressure, temperature, level, flow, and force measurement. A global leader in lean manufacturing, WIKA has manufacturing locations around the globe, which enables flexibility and the ability to meet high delivery demands.

Ashcroft’s extensive product line is the benchmark in pressure and temperature measurement, including pressure gauges. Used globally in the most demanding environments, our instruments are known under the names Ashcroft®, Heise®, Willy® and Weksler® and offer multi-industry versatility. As a leader in technology and innovation, we design new products for current and emerging market...

Endress + Hauser makes highly accurate equipment with electric output signals, which function as digital process pressure and differential pressure gauges. Our differential pressure gauges measure dusts, gases, liquids and vapors. Ceraphant is our pressure switch used in absolute and pressure gauges.

More Fuel Pressure Gauge Manufacturers

Components of Fuel Pressure Gauges

Fuel pressure gauges are made up of several components, including the gauge body, Bourdon tube, pressure fitting, connecting hose, and needle and dial. These components are explained below.

The Gauge Body

The gauge body is the outer casing of the fuel pressure gauge that houses the other components. It is typically made of metal or plastic and can have different shapes and sizes depending on the specific application.

The Bourdon Tube

The Bourdon tube is a coiled metal tube inside the gauge body that expands and contracts in response to changes in pressure. As the fuel pressure changes, the Bourdon tube moves, and this movement is transmitted to the needle and dial.

The Pressure Fitting

The pressure fitting is the part of the gauge that connects to the fuel system and measures the fuel pressure. It is usually a threaded metal fitting that screws into the fuel system.

The Connecting Hose

The connecting hose is a flexible hose that connects the pressure fitting to the gauge body. It is typically made of rubber or plastic and can vary in length and diameter depending on the specific application.

The Needle and Dial

The needle and dial are the components that provide the readings of the fuel pressure. The needle moves along a scale on the dial to show the current fuel pressure.

Variations of Fuel Pressure Gauges

Fuel pressure gauges can come in different designs and specific application variations, such as:

Mechanical Fuel Pressure Gauges

These gauges use the Bourdon tube to measure the fuel pressure and display the readings on the dial. They are typically the most common type of fuel pressure gauge and can be found in automotive, marine, and industrial applications.

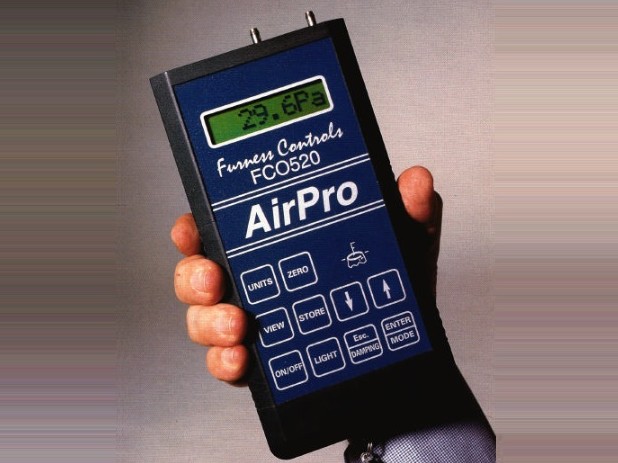

Digital Fuel Pressure Gauges

These gauges use sensors to measure the fuel pressure and display the readings on a digital screen. They are typically more accurate than mechanical gauges but can be more expensive.

Electric Fuel Pressure Gauges

These gauges use an electric sender unit to measure the fuel pressure and transmit the readings to a gauge on the dashboard. They are typically used in modern vehicles and can be more accurate than mechanical gauges.

Considerations Regarding Fuel Pressure Gauges

Fuel pressure gauges do have some challenges that should be considered. For example, they can be affected by vibration, temperature changes, and other factors that can cause inaccuracies in the readings. Additionally, fuel pressure gauges can be prone to wear and tear over time, which can affect their accuracy and reliability. It is important to regularly check and calibrate fuel pressure gauges to ensure accurate readings.

Benefits of Fuel Pressure Gauges

Meanwhile, fuel pressure gauges have benefits in terms of improving engine performance, fuel economy, and early detection of fuel system issues. By monitoring the fuel pressure levels in a fuel system, fuel pressure gauges can help optimize the fuel delivery and combustion process, leading to better engine performance and improved fuel economy. Additionally, fuel pressure gauges can detect any issues with the fuel system early on, which can help prevent further damage to the engine and reduce the risk of costly repairs.

Applications of Fuel Pressure Gauges

Fuel pressure gauges are used in various applications, including automotive, marine, aviation, and industrial. We examine these applications in greater detail below.

Automotive

Fuel pressure gauges are commonly used in automotive applications to monitor fuel pressure in the fuel system. They can help improve engine performance, fuel economy, and early detection of fuel system issues.

Marine

Fuel pressure gauges are used in marine applications to monitor fuel pressure levels in marine engines and detect any issues with the fuel system.

Aviation

Fuel pressure gauges are essential in aviation applications to monitor fuel pressure in aircraft engines. It is crucial to have accurate readings of fuel pressure in the fuel system of an aircraft to ensure safe operation.

Industrial

Fuel pressure gauges are also used in industrial applications, such as in manufacturing plants, power plants, and mining equipment. They can help monitor fuel pressure in various types of industrial equipment and detect any issues with the fuel system.

Choosing the Proper Fuel Pressure Gauge Supplier

To ensure you have the most satisfying outcome when purchasing fuel pressure gauges from a fuel pressure gauge supplier, it is important to compare several companies using our directory of fuel pressure gauge suppliers. Each fuel pressure gauge supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each fuel pressure gauge business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple fuel pressure gauge companies with the same form.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services