Water pressure gauges measure water pressure and check water flow. These tools can be used on both commercial and residential properties to gauge the pressure in wells, irrigation systems, and sprinklers. A water pressure gauge can also detect issues with indoor plumbing or outdoor irrigation systems. Read More…

At AMETEK® U.S. Gauge, PMT Products, we take pride in designing and manufacturing precision pressure gauges that set the standard for performance and reliability. We specialize in creating instruments that deliver accurate readings under the most demanding industrial conditions, ensuring dependable operation across a wide range of applications.

We take pride in offering a wide range of pressure gauges designed to deliver precision, reliability, and durability across industrial applications. At Emerson, we engineer our gauges to meet the demands of challenging environments where accurate pressure monitoring is critical to performance and safety.

Since 1946, WIKA has continuously advanced instrumentation for pressure, temperature, level, flow, and force measurement. A global leader in lean manufacturing, WIKA has manufacturing locations around the globe, which enables flexibility and the ability to meet high delivery demands.

Ashcroft’s extensive product line is the benchmark in pressure and temperature measurement, including pressure gauges. Used globally in the most demanding environments, our instruments are known under the names Ashcroft®, Heise®, Willy® and Weksler® and offer multi-industry versatility. As a leader in technology and innovation, we design new products for current and emerging market...

Endress + Hauser makes highly accurate equipment with electric output signals, which function as digital process pressure and differential pressure gauges. Our differential pressure gauges measure dusts, gases, liquids and vapors. Ceraphant is our pressure switch used in absolute and pressure gauges.

More Water Pressure Gauge Manufacturers

A water system's pressure may be static or dynamic. Static means the pressure in a water system is not flowing and is constant in all directions. Dynamic pressure is the extra pressure brought on by the fluid's flow direction. Dynamic pressure aids in measuring flow rates and reveals a water system's flowing pressure, although it has little effect on surfaces parallel to the flow direction.

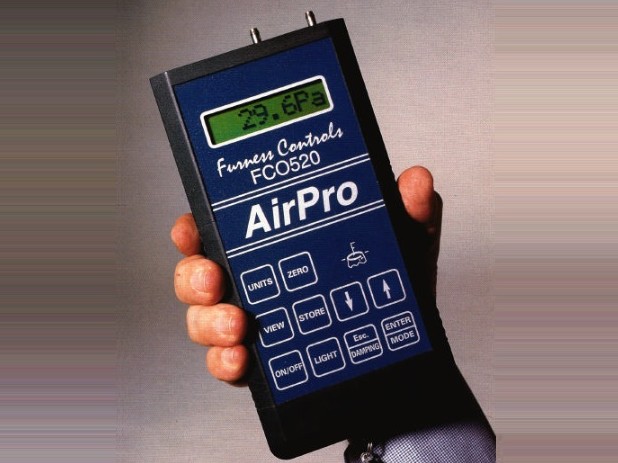

Differential pressure is measured in the form of dynamic pressure. Water pressure gauges calculate the system's gauge pressure. The absolute pressure is also zero-referenced against a pure vacuum, whereas the gauge pressure is the absolute pressure with less ambient pressure.

Dynamic Pressure

Differential pressure gauges calculate the difference in water pressure between two chambers isolated from one another by a moving element that responds to changes in pressure. The pointer on that gauge face or the reading on the digital display moves in response to the movement of the element. A pressure drop is visible on the gauge since one of the gauge's ports is on the high side and the other is on the low side.

Sometimes a rotary magnet attached to the gauge pointer or digital display is pulled by a linear magnetic piston positioned between the two pressure chambers. Due to their simplicity, differential pressure gauges are widely used.

Selection Criteria for Water Pressure Gauge

When selecting the best water pressure gauge for any application, there are many factors to consider. Below are some of the most important parameters.

Measuring Range

The operating pressure range of the process is the main factor considered when choosing water pressure gauges. On the indication scale, the range is shown as 0 to a maximum pressure which is the gauge pressure. The chosen measuring range determines the scale division. The size of the unit shift that may be determined from the indication is known as the scale division. A water pressure gauge with a maximum pressure that closely matches and works best for the application should be selected. A pressure gauge's measurements will be erroneous if its maximum pressure range is too high for the task.

Accuracy

The pressure gauge, which can be used for anything from basic testing to monitoring intricate industrial water processes, determines the level of accuracy necessary. A common rule of thumb is that testing pressure gauge accuracy should range from 0.25 to 0.10 percent on the whole scale, whereas important procedures require a precision of 0.5 percent. Accuracy levels for less crucial procedures can reach 2%.

Connection Location

Water pressure gauge connections come in a variety of sizes. In most cases, the dimensions are expressed in inches. When the pipe is relatively tiny, or there is already a holding connection for the water pressure gauge, the choice of connection size is crucial. More significant than size is the connection type. An external thread cylindrical connector that makes straightforward replacement possible is extremely prevalent.

The fact that the connection is intended to link the gauge to the application is an important consideration. More flexibility may be possible depending on the location and size of the connection. For example, an upward-facing female connection can attach a lower mount gauge, but a backward-facing connector makes it difficult to read the gauge.

IP Protection

When utilizing the water pressure gauge in an area with dust, moisture, or water splashes, the IP code is crucial. Higher IP ratings will also increase the gauge's price.

Maximum Operating Temperature

Most water pressure gauges function well at temperatures above 140 to 176 degrees Fahrenheit (60 to 80 °C). For use in high-temperature settings, specific water pressure gauges are available.

Water Pressure Gauge Applications

- Pool Filter Pressure Gauge: Monitoring pressure changes inside a pool system is easier with a pool filter pressure gauge. High pressure following a baseline reading of pressure often indicates that the filter needs to be cleaned, whereas low pressure denotes a flow problem.

- Irrigation and Sprinkler System: Water pressure gauges are used to show the pressure in a farm's irrigation system or a garden's sprinkler system.

- Detection of Leakages: Water pressure gauges are mounted in the loop to detect a leak in a closed water loop, such as a heating circuit or even a process line.

- Well Pressure: Water pressure gauges are used in homes with well-fed freshwater systems to detect low well pressure. This makes it easier to prepare for additional water sources or to drill a new well.

Choosing the Proper Water Pressure Gauge Supplier

To make sure you have the most positive outcome when purchasing Water Pressure Gauges from a Water Pressure Gauge Supplier, it is important to compare at least 5 Manufacturers using our list of Water Pressure Gauge suppliers. Each Water Pressure Gauge Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Water Pressure Gauge business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Water Pressure Gauge companies with the same message.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services