They indicate the internal pressure within vessels or systems and are used particularly for environments where the pressure changes frequently, therefore requiring constant monitoring. Read More…

At AMETEK® U.S. Gauge, PMT Products, we take pride in designing and manufacturing precision pressure gauges that set the standard for performance and reliability. We specialize in creating instruments that deliver accurate readings under the most demanding industrial conditions, ensuring dependable operation across a wide range of applications.

We take pride in offering a wide range of pressure gauges designed to deliver precision, reliability, and durability across industrial applications. At Emerson, we engineer our gauges to meet the demands of challenging environments where accurate pressure monitoring is critical to performance and safety.

Since 1946, WIKA has continuously advanced instrumentation for pressure, temperature, level, flow, and force measurement. A global leader in lean manufacturing, WIKA has manufacturing locations around the globe, which enables flexibility and the ability to meet high delivery demands.

Ashcroft’s extensive product line is the benchmark in pressure and temperature measurement, including pressure gauges. Used globally in the most demanding environments, our instruments are known under the names Ashcroft®, Heise®, Willy® and Weksler® and offer multi-industry versatility. As a leader in technology and innovation, we design new products for current and emerging market...

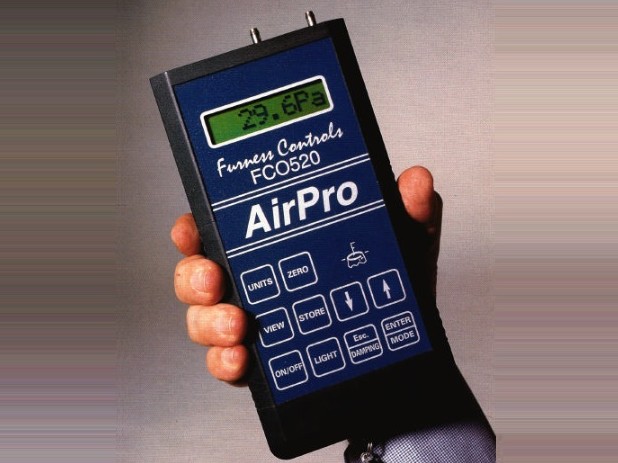

Endress + Hauser makes highly accurate equipment with electric output signals, which function as digital process pressure and differential pressure gauges. Our differential pressure gauges measure dusts, gases, liquids and vapors. Ceraphant is our pressure switch used in absolute and pressure gauges.

More Differential Pressure Gauge Manufacturers

A differential pressure gauge's components are housed in a metal enclosure; materials include stainless steel, cast iron, bronze, brass and aluminum. The windows are usually double-strength glass. Specific pressure gauges have additional materials such as plastic or rubber. Differential liquid pressure gauges are themselves filled with certain liquids including oil, glycerin and silicone. Pressure gauges are often used in tandem with protective accessories like shutoff valves.

Other accessories include pipe coils, chemical seals and secondary valves to minimize condensation and to allow calibration against an external pressure source such as atmospheric pressure. Differential pressure gauges have two inlet ports that monitor the pressure in two separate vessels. These pressure gauges are used in applications where it is important to take two measurements and compare them, determining which vessel or system has the highest flow velocity, for example. Differential pressure gauges are utilized by manufacturing and industrial plants and companies.

Differential pressure gauges perform subtraction in order to indicate the difference between the two readings. This eliminates the need for an operator or computer system to watch two gauges and perform the math. It is fast and efficient to have the information immediately and constantly displayed in one location. There are three main types of differential pressure gauges: Bourdon, diaphragm and piston. The Bourdon gauge has two C-shaped or coiled tubes connected to the chambers or pipes where the pressures must be read.

When pressure increases, the tubes uncoil. The motion of the two tubes is registered and a mechanical linkage compares the readings. Diaphragm gauges use two hermetically sealed membranes that flex in accordance with the pressure. The ports of the membranes are open to each other to compare pressures.

Piston type differential pressure gauges are also called deadweight testers because they counterbalance the pressure of a fluid with a solid weight or spring. As is the case with all three kinds, the difference is measured by a sensor and indicated on the gauge. The results may be displayed as analog, such as a needle on a dial, or they may be digital with numbers on a LED panel.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services