A gas pressure gauge is an indispensable device in LPG and other gas applications for ensuring a predictable and reliable operation. It is designed to measure the fluid intensity and identify pressure changes and leaks that can negatively impact an operation. The installation of gas pressure gauges can be convex, direct installation, or embedded installation. Read More…

At AMETEK® U.S. Gauge, PMT Products, we take pride in designing and manufacturing precision pressure gauges that set the standard for performance and reliability. We specialize in creating instruments that deliver accurate readings under the most demanding industrial conditions, ensuring dependable operation across a wide range of applications.

We take pride in offering a wide range of pressure gauges designed to deliver precision, reliability, and durability across industrial applications. At Emerson, we engineer our gauges to meet the demands of challenging environments where accurate pressure monitoring is critical to performance and safety.

Since 1946, WIKA has continuously advanced instrumentation for pressure, temperature, level, flow, and force measurement. A global leader in lean manufacturing, WIKA has manufacturing locations around the globe, which enables flexibility and the ability to meet high delivery demands.

Ashcroft’s extensive product line is the benchmark in pressure and temperature measurement, including pressure gauges. Used globally in the most demanding environments, our instruments are known under the names Ashcroft®, Heise®, Willy® and Weksler® and offer multi-industry versatility. As a leader in technology and innovation, we design new products for current and emerging market...

Endress + Hauser makes highly accurate equipment with electric output signals, which function as digital process pressure and differential pressure gauges. Our differential pressure gauges measure dusts, gases, liquids and vapors. Ceraphant is our pressure switch used in absolute and pressure gauges.

More Gas Pressure Gauge Manufacturers

Types of Gas Pressure Gauges

Gas pressure gauges are essential components in industrial, commercial, and laboratory environments where monitoring and controlling gas pressure is critical. Understanding the different types of gas pressure gauges available can help ensure you select the correct device for your specific application, whether you need to measure low, medium, or high gas pressures. Below, we explore the main types of gas pressure gauges, their operating principles, and key use cases to help you make a more informed purchasing decision.

Bourdon Tube Pressure Gauge

The Bourdon tube pressure gauge is the most widely used type of mechanical pressure gauge worldwide and is especially prevalent in gas pressure measurement for both industrial and laboratory settings. Its robust design and reliability make it ideal for a broad spectrum of applications, from compressed gas systems to process control and HVAC operations. The Bourdon tube itself is typically constructed from steel or other corrosion-resistant materials, ensuring longevity and durability even in environments with heavy vibration, pulsating pressure, or exposure to aggressive gases.

This mechanical gauge operates without the need for electricity, making it suitable for remote or hazardous locations where electrical components may pose safety risks. The Bourdon tube flexes under pressure, translating the force into a readable value via a needle or digital display. Users often select Bourdon tube gauges for their accuracy, ease of use, and ability to withstand harsh operating conditions, especially where mechanical resilience is a priority.

Diaphragm Pressure Gauge

Diaphragm pressure gauges, also known as membrane pressure gauges, are specifically engineered for measuring low-pressure intensities in gas or liquid systems. The core of this instrument is a highly sensitive, flexible diaphragm that responds to minute pressure changes, making it perfect for applications requiring precise low-pressure measurement such as ventilation systems, gas regulation, and environmental monitoring.

The working principle of the diaphragm gauge is based on the deflection of a thin, elastic membrane. When pressure is applied, the diaphragm flexes, and this movement is translated mechanically to a needle or digital indicator. Diaphragm gauges are favored for their compact design, high sensitivity, and compatibility with both corrosive and non-corrosive gases. These gauges can cover a wide pressure range, from as low as 0.6 bar up to 7000 bar, making them suitable for both low and high-pressure applications. The pinion mechanism ensures accurate and repeatable readings, even under dynamic pressure conditions.

Capsule Pressure Gauge

Capsule pressure gauges are designed for measuring very low pressures, particularly in gaseous environments. These devices utilize two corrugated diaphragms welded at their circumference to form a capsule, which is sensitive to small pressure changes. When pressure is introduced, the capsule expands or contracts, and this mechanical action is translated into a readable value. Capsule pressure gauges are commonly used for measuring pressures up to 600 mbar (millibar) and provide highly accurate results for air, inert gases, and other non-corrosive gases.

Typical applications include monitoring gas distribution lines, cleanroom environments, and medical gas supply systems, where precision at low-pressure ranges is vital. The unique capsule design ensures stability and repeatability, making these gauges indispensable in specialized industries.

Absolute Pressure Gauges

Absolute pressure gauges are designed to measure pressure independently from atmospheric fluctuations—providing a true reading relative to a perfect vacuum. This is achieved by fixing a reference vacuum chamber on one side of the measuring element, which remains unaffected by external pressure or altitude changes. Absolute pressure gauges are especially crucial in scientific laboratories, aeronautics, HVAC (heating, ventilation, and air conditioning), and process industries where accurate, uncompromised data is essential for quality control and regulatory compliance.

Use cases include monitoring barometric pressure, vacuum process control, and research applications where small deviations in atmospheric pressure can significantly affect results. Their resistance to external variables makes them a trusted choice for environments where precision is paramount.

Differential Pressure Gauge

Differential pressure gauges play a vital role in applications where it is necessary to monitor the difference in pressure between two points in a system. These gauges consist of two chambers separated by a sensitive element, often a diaphragm, which moves in response to pressure changes on either side. The resulting movement is converted into a measurable value, helping users identify system imbalances, detect filter blockages, or optimize flow rates.

A differential pressure gauge is indispensable for monitoring filters, pumps, and flow systems in water treatment plants, chemical processing, pharmaceutical manufacturing, and HVAC installations. By providing real-time feedback on system performance, differential gauges help maintain safety, efficiency, and regulatory compliance in critical process environments.

Bellows Pressure Gauge

Bellows pressure gauges are mechanical devices that measure both absolute and differential pressure, leveraging the expansion and contraction of a thin-walled, accordion-shaped bellows element. The bellows' large surface area allows for precise measurement of very low pressures, making these gauges ideal for sensitive gas and vacuum applications. The force generated by pressure changes is transferred to a transmission mechanism, providing a clear and accurate pressure reading.

This type of pressure gauge is frequently used in leak testing, laboratory vacuum systems, and low-pressure gas monitoring. The flexible metal tubes are resistant to fatigue and corrosion, ensuring a long operational life even under demanding conditions. Bellows gauges are selected for their high sensitivity, reliability, and ability to function in environments where other gauge types might be less effective.

Manometer Pressure Gauge

Manometer pressure gauges are among the oldest and simplest devices for measuring gas pressure. They operate on the principle of balancing a column of fluid against the pressure to be measured. Typically, one end of the manometer is connected to the gas pressure source, while the other is open to the atmosphere, providing a straightforward method for determining pressure differences.

Manometers are often used in laboratory settings, calibration facilities, and HVAC applications. Their simplicity, accuracy, and lack of moving parts make them ideal for applications where high precision is required, and routine maintenance needs to be minimized.

Applications of Gas Pressure Gauges

Gas pressure gauges are essential across a diverse range of industries and applications. Their ability to provide accurate, real-time pressure readings is critical for ensuring safety, efficiency, and regulatory compliance. Here are some of the most common and high-value use cases for gas pressure gauges:

- They are used to inspect air brakes on trucks, ensuring the safe operation of commercial vehicles by monitoring air pressure in braking systems.

- They are utilized in refrigeration systems and HVAC (heating, ventilation, and air conditioning) to monitor and control the pressure of refrigerants and gases, ensuring optimal operation and energy efficiency.

- They are utilized for eliminating potential leak paths in gas pipelines, distribution systems, and storage tanks, helping to prevent hazardous leaks and maintain workplace safety.

- Gas pressure gauges are used in gas supply systems and gas transmission networks to track and regulate pressure, supporting the reliable delivery of natural gas, compressed air, and other industrial gases.

- In laboratory and research environments, gas pressure gauges are employed to monitor vacuum systems, gas chromatography, and other sensitive applications requiring precise pressure management.

- Industrial manufacturing facilities use gas pressure gauges to optimize production processes, maintain product quality, and minimize downtime related to pressure-related issues.

- In medical applications, gas pressure gauges ensure safe and effective delivery of medical gases such as oxygen and anesthetic agents to patients.

- Power generation plants utilize gas pressure gauges to monitor and control the flow and pressure of fuel gases, supporting efficient and safe plant operations.

- Chemical and petrochemical processing industries rely on gas pressure gauges to ensure compliance with safety standards and to maintain optimal process conditions.

- Food and beverage manufacturers use gas pressure gauges to manage the carbonation process and monitor CO2 levels in production lines.

No matter the industry, selecting the right gas pressure gauge for your specific application is essential for achieving accurate monitoring, reducing operating costs, and ensuring long-term reliability.

Benefits of Gas Pressure Gauges

Investing in high-quality gas pressure gauges delivers a wide range of benefits, supporting both operational efficiency and safety objectives. Below are some of the key advantages that gas pressure gauges offer businesses and organizations across industries:

- Their safety is increased in hard operating conditions, such as extreme temperatures, vibrations, and exposure to corrosive gases. Robust construction and reliable performance help prevent accidents and equipment failures.

- They help in the reduction of costly downtime by providing real-time monitoring and early detection of pressure anomalies, allowing for preventive maintenance before major issues arise.

- They are very suitable for aggressive environments, including chemical processing, oil and gas, and power generation, due to their corrosion-resistant materials and durable designs.

- Their design is robust and constructed from high-quality materials, ensuring long service life and minimal maintenance requirements even in demanding industrial applications.

- They provide accurate pressure readings, supporting process optimization, regulatory compliance, and improved product quality.

- Gas pressure gauges offer versatility, with models designed for measuring absolute, gauge, and differential pressure across a broad range of pressures and media types.

- They support energy efficiency by enabling precise control and monitoring of gas flow in process systems, helping to reduce operational costs over time.

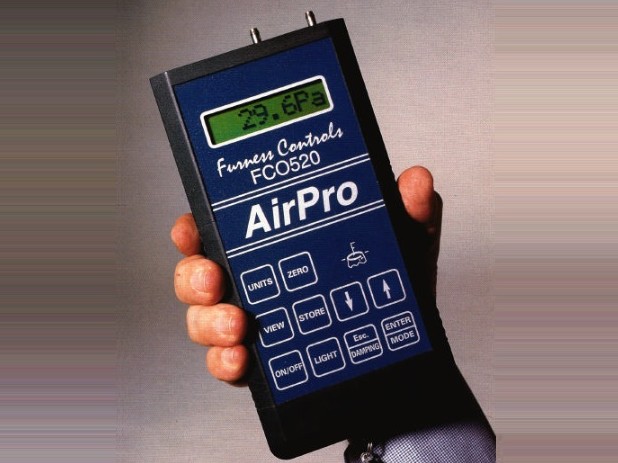

- Advanced models may feature digital displays, remote monitoring capabilities, and data logging, supporting integration with modern automation systems and IoT (Internet of Things) platforms.

- Easy installation and user-friendly designs make gas pressure gauges accessible to operators and technicians at all skill levels.

- Compliance with international standards ensures that gas pressure gauges meet rigorous safety and quality requirements for critical applications.

By leveraging the advantages of modern gas pressure gauges, organizations can improve process control, enhance safety, drive cost savings, and maintain high standards of regulatory compliance.

How to Select the Right Gas Pressure Gauge for Your Needs

Choosing the optimal gas pressure gauge for your application requires careful consideration of several important factors. Here are key decision points to guide your selection process and ensure the best fit for your operational requirements:

- Pressure Range: Select a gauge that covers the required measurement range in your application, allowing a safety margin for pressure spikes or fluctuations. Consider whether you need to measure low, medium, or high pressures.

- Type of Pressure: Determine whether you need to measure gauge, absolute, or differential pressure. Applications such as leak detection or process monitoring may require specific types of gauges.

- Process Media: Ensure the gauge material is compatible with the gas type (e.g., oxygen, natural gas, ammonia, inert gases) to prevent corrosion or contamination.

- Environmental Conditions: Factor in ambient temperature, humidity, vibration, and exposure to chemicals or dust. Select gauges designed for the specific environmental challenges of your operation.

- Accuracy Requirements: Define the level of accuracy necessary for your application. Critical processes may require high-precision gauges with low error margins.

- Mounting and Installation: Consider available space, mounting orientation (panel, wall, or pipe), and connection type (threaded, flanged, welded) for straightforward installation and maintenance.

- Signal Output and Integration: For automated or remote monitoring applications, look for gauges with electronic or digital outputs that can integrate with PLCs, SCADA, or IoT systems.

- Certifications and Compliance: Confirm that the gauge meets relevant industry standards and safety certifications, particularly for applications in hazardous or regulated sectors.

- Maintenance and Calibration: Assess the ease of calibration and ongoing maintenance, especially if the gauge will be used in critical or high-frequency operations.

- Cost and Total Value: Evaluate not only the initial purchase price but also the total cost of ownership, including installation, maintenance, reliability, and expected service life.

By addressing these key factors, you can confidently select a gas pressure gauge that delivers accurate, reliable performance and long-term value in your unique operational environment.

Choosing the Right Gas Pressure Gauge Manufacturer

Finding a trusted gas pressure gauge manufacturer or supplier is a critical step in ensuring the quality, performance, and reliability of your pressure measurement solution. The right supplier will offer a comprehensive portfolio of gas pressure gauges, technical support, and customization options to meet your specific needs. Here’s how you can streamline your sourcing process for optimal results:

- Compare Multiple Suppliers: To make sure you have the most constructive outcome when purchasing Gas Pressure Gauges from a Gas Pressure Gauge Supplier, it is important to compare at least 4 Suppliers using our list of Gas Pressure Gauge manufacturers. Evaluating multiple suppliers enables you to assess product quality, pricing, and lead times.

- Review Business Profiles: Each Gas Pressure Gauge Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Use these profiles to identify manufacturers with relevant industry expertise and a proven track record.

- Explore Company Specializations: Review each Gas Pressure Gauge business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Gas Pressure Gauge companies with the same form. This ensures efficient and comprehensive communication.

- Request Technical Support: Leading manufacturers provide technical documentation, calibration services, and engineering support to help you select the most suitable gauge for your application.

- Customization and Innovation: If your application requires unique specifications, such as specialized materials, enhanced accuracy, or digital integration, seek out manufacturers with customization capabilities and innovative product lines.

- Evaluate After-Sales Service: Reliable suppliers offer warranty coverage, repair services, and ongoing support to maximize the lifespan and performance of your gas pressure gauges.

- Check Certifications: Confirm that manufacturers comply with international quality standards, such as ISO 9001, and industry-specific certifications for safety and performance.

Carefully selecting a reputable gas pressure gauge manufacturer or supplier will ensure you receive products that meet your technical requirements, budget constraints, and long-term operational goals. A collaborative supplier relationship can also provide valuable insights into emerging technologies and industry best practices.

Frequently Asked Questions About Gas Pressure Gauges

What factors affect the accuracy of a gas pressure gauge?

Accuracy can be influenced by several factors, including the quality of the gauge, environmental conditions (temperature, vibration, humidity), the type of gas being measured, and whether the device has been properly calibrated and maintained. Regular calibration and using gauges designed for the specific application help ensure reliable results.

How often should gas pressure gauges be calibrated?

Calibration frequency depends on the criticality of the application, manufacturer recommendations, and regulatory requirements. In most industrial environments, calibration is recommended annually, but high-precision or safety-critical applications may require more frequent checks.

Can gas pressure gauges be used for liquid applications?

Some gas pressure gauges, such as Bourdon tube and diaphragm gauges, can also be used for liquid applications if the materials are compatible with the media. However, it is important to select a gauge specifically rated for the intended fluid to avoid corrosion or measurement errors.

What are the common causes of gas pressure gauge failure?

Common causes include mechanical fatigue, overpressure events, exposure to corrosive gases or liquids, blocked pressure ports, and improper installation. Routine inspection and choosing gauges designed for the application environment can minimize the risk of failure.

Are digital gas pressure gauges better than analog gauges?

Digital gas pressure gauges offer features like higher accuracy, remote monitoring, and data logging, making them ideal for advanced process control and automation. Analog gauges remain popular for their simplicity, mechanical reliability, and ease of reading in harsh environments. The choice depends on your application requirements and budget.

How do I know if my gas pressure gauge needs to be replaced?

Signs that a gauge should be replaced include erratic readings, visible damage, failure to return to zero, or an inability to calibrate to the required accuracy. Replacing faulty gauges helps ensure safety and process reliability.

Conclusion

Gas pressure gauges are vital tools for accurately monitoring and controlling gas pressure in a wide array of industries and applications. By understanding the different types of gas pressure gauges, their key features, and selection criteria, you can make informed decisions that enhance operational safety, efficiency, and compliance. Whether you require a robust mechanical gauge for industrial use, a high-precision device for laboratory work, or a digital solution for remote monitoring, selecting the right gas pressure gauge and trusted supplier will ensure long-term success and peace of mind.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services